1. What does LOTO stand for?

LOTO, known in the working world as Lockout/Tagout, is a vital safety strategy used to protect a facility’s workers from being harmed by hazardous energy. Hazardous energy is defined as the potential stored energy in equipment that may suddenly be released when workers are servicing equipment. This type of energy can be expressed electrically, chemically, mechanically, hydraulically, thermally, and pneumatically. The release of hazardous energy can be unpredictable and can ultimately cause severe harm or even death to workers who are performing a task on a specific piece of equipment.

2. How does lockout/tagout improve safety?

The Lockout/tagout program is one of the most important safety improvement strategies used in workplaces today. It is a relatively simple system that has helped to save many people’s lives, and prevent even more injuries, over the years. Understanding how lockout/Tagout improves safety will show why it is so important to implement in the workplace.

3. Is lockout/tagout required by OSHA?

It is well-known that the lockout/tagout system is will help to improve safety in the workplace. According to the latest statistics, using lockout/tagout has saved hundreds of lives and prevented thousands of injuries since it has been widely used in manufacturing and other industries. While the fact that it is so effective should be reason enough to use it, some companies only implement safety improvements if it is required of them. This is why many people ask if LOTO is required by OSHA.

The simple answer is yes. OSHA does require that companies use the lockout/tagout system in many different situations. It is identified in a variety of different places within the OSHA regulations, but in general a company should know that they have to use it whenever control of hazardous energy is a priority.

4. What are lockout/tagout devices?

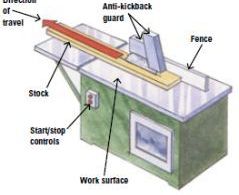

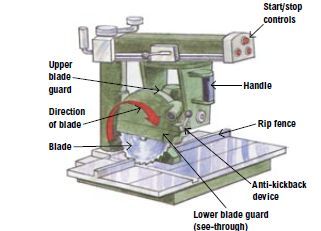

When using the lockout/tagout procedure it is necessary to place a physical device on either the electrical supply cord, or the place where the machinery in question is plugged in. These are the items that will stop other people from inadvertently energize a machine, putting the person in or around it in danger. There are quite a few different types of LOTO devices that a company can use. Knowing about these devices, and the ways they work, can help ensure you pick the right one for your facility.

Padlock Devices.

Padlock style LOTO devices are placed on the plug or other part of the electrical system to ensure that it physically can’t be used. There are a number of different sizes and types of padlock that can be used, so make sure to choose one that will be able to be secured to the area where it will be used in your facility. This, and all lockout devices, should say “LOCKED OUT” and “DANGER” right on them so people know why they are there.

Clamp-On Breaker Devices.

A clamp-on breaker style LOTO device will open up and then clamp down onto the electrical points to ensure power can’t be restored while in place. This option often fits a wider range of different electrical system, which is why it is quite popular in many facilities. This kind of device is usually red in color so it will easily stand out.

Lockout Box Device.

A LOTO box style device simply fits around the electrical plug and closes around the cord. The box is then locked so that it can’t be opened. Unlike many other styles, this one doesn’t fit snugly on the actual prongs of the power cord, but rather isolates it in a large box or tube structure that can’t be opened without the key.

Other Styles of LOTO Device.

There are a variety of other types and styles of lockout/tagout devices that are available too. Some companies even have custom devices built so they fit the exact situation where they will be used. No matter what type of device you are using, you’ll want to make sure that it is able to physically prevent a power cord or other power source from being plugged in. When these devices are used properly, they can help to keep everyone in the facility safer.

5. What are lockout/tagout tags?

In the lockout/tagout procedure, the person who is working in a potentially dangerous area will need to attach a tag to the lock that they are putting on the power cord or other power supply. This tag is where the procedure gets the second half (tag out) of its name. Understanding what a LOTO tag is, and what purpose it serves, is important for successfully implementing this type of safety program in your facility.

These tags are attached to the lock when removing a power source from a machine. In general, one tag should be applied to each lock.

6. What is a lockout/tagout station?

When it comes to implementing the lockout/tagout program in a facility, nothing makes it easier or more effective than a LOTO station. This is a simple place where you can store all the various components of the LOTO program so that they are all easy to find whenever you need them. In addition, this type of station will also make it easy for employees to return everything to where it belongs so that it doesn’t get misplaced or damaged.

7. What is the main goal for a lockout/tagout program?

The main goal for a lockout/tagout (LOTO) program is to improve the safety of employees who work on potentially dangerous machines. Specifically, it will prevent a machine from being powered up while workers are performing maintenance in a potentially hazardous area. The concepts behind the LOTO program are quite simple, but they have been proven to be extremely effective at minimizing some of the most severe types of workplace accidents and injuries.

8. When should lockout/tagout be used?

A good lockout/tagout (LOTO) program should be used to help protect employees, contractors, vendors, and others from the dangers of working in and around dangerous machinery. Any time someone is going to enter into a machine or a hazardous area, the power should be removed and locked out so that the machine can’t be accidentally engaged. While there is no doubt that this can be a very effective safety strategy for any facility, many people don’t know exactly when it should be used.

Performing Routine Maintenance.

When maintenance professionals enter a hazardous area of a machine to perform routine work, the lockout/tagout program must be used. Large machinery often needs to have fluids changed, parts greased, gears replaced, and much more. If someone has to enter the machine, the power should always be locked out to keep the maintenance personnel safe.

Inspecting Machine for Problems.

If a machine is performing abnormally it may be necessary to get up close and inspect it for problems. Simply turning the machine off to do this type of work is not sufficient. If it should start moving unexpectedly, the people performing the inspections could be seriously injured or even killed. The fact that the machine is performing abnormally already is only further indication that all power sources need to be removed and locked out to avoid an accident.

Repairing Broken Equipment.

If something is broken on a machine, it will need to be repaired or replaced right away. The lockout/tagout program will provide a safe environment so that the technicians or other repair teams can come in and work comfortably without fear of an accident or injury occurring due to the machine starting up unexpectedly.

Retooling Machinery.

There are many times when a machine needs to be retooled or otherwise adjusted so that it can be used to make a different model or even a different product. When this is being done, people will almost always have to be working in potentially dangerous areas. If the power is left on, someone could start it up without realizing that the retooling was being done. A good lockout/tagout program will help ensure this cannot happen.

9. Who benefits from LOTO?

The lockout/tagout program is designed to help improve safety in a facility. When implemented correctly, it can help to dramatically reduce the risk that someone or something will be in danger when working in or around machinery. This can include protections from being crushed, hit by moving parts, electrocuted, cut, or experience other types of injuries. Many people benefit from the LOTO program, which is one of the major reasons why it has become such a vital part of many facility safety systems.

10. Why should a facility implement a LOTO program?

When managing a workplace, it is important to do everything possible to ensure the safety of employees and the facility itself. There are many different programs and strategies that can be used in this area, so choosing the right ones for a given situation can be difficult. When it comes to minimizing the hazards of working in and around dangerous machinery, the lockout/tagout program is a great (and often required) option. It provides protection from very serious hazards and has been proven effective for years.